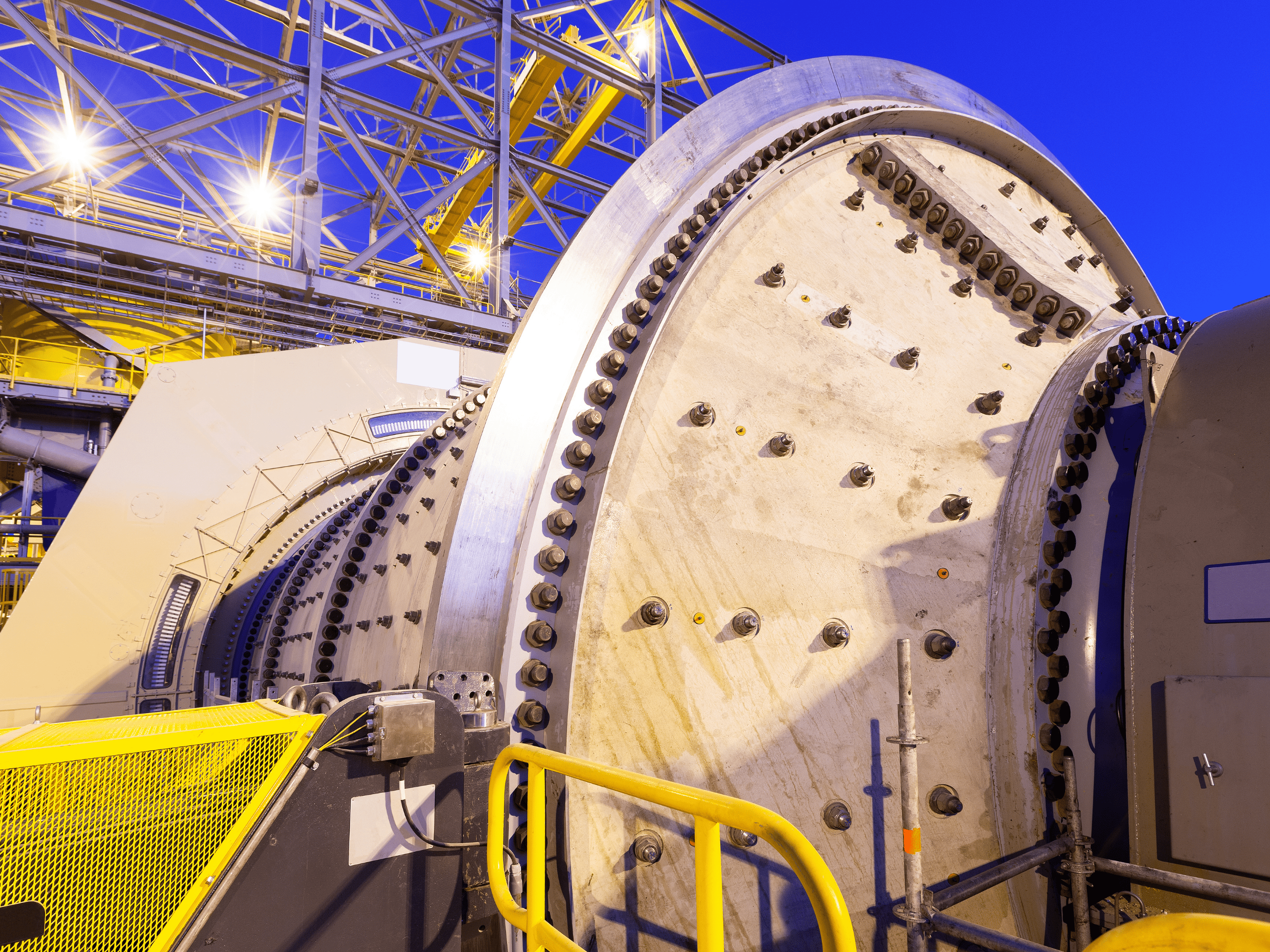

Mill Liners

Mill Lining Solutions for Optimal Grinding Performance

Enhance the efficiency, safety, and profitability of your milling operations with our comprehensive range of mill lining solutions. We deliver customized, high-performance products designed to meet the demands of AG, SAG, Ball, and Rod Mills.

Our mill linings are engineered to withstand the toughest conditions—reducing downtime, increasing throughput, and lowering total cost of ownership. From lifter bars and shell plates to trunnion liners and center cones, every component is meticulously designed and manufactured using state-of-the-art engineering tools. This advanced design process ensures optimal fit, extended wear life, and superior grinding efficiency.

Why Choose Our Mill Liners?

Leveraging decades of global experience, our solutions incorporate rubber and composite materials that reduce noise, minimize bearing wear, and eliminate particle lock-up, all while delivering excellent sealing properties. Enhanced safety features include lighter-weight components that simplify installation and maintenance.

We provide full-service support—on-site audits, wear inspections, liner optimization consultations, and timely maintenance services—to keep your milling circuit running at peak performance. From concept to delivery, our custom design and fabrication processes guarantee that each mill lining solution matches your specific operational needs. Trust our integrated approach, backed by extensive technical application expertise, to help you achieve maximum productivity, throughput, and cost savings in your grinding operations.

Our solutions drive success, ensuring your operations run smoothly every day.